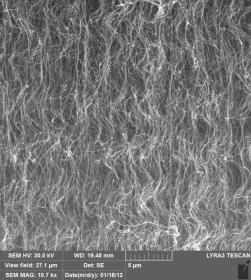

Side view of the "forest" of carbon naotubes. From the article by N.G. Chechenin et al Appl. Surf. Sci. (2013) v. 275, p. 217-221

A group of scientists of the Atomic Nuclei Physics Department of SINP specialized in the field of nanocomposite materials develops methods for synthesis of carbon nanotubes and study their possible application. Professor, DSc. Nikolay Chechenin told us about this research direction in details.

- Professor, please, tell us about your studies of carbon nanotubes.

- I think I'll begin from the basic terms. Carbon is one of the most important elements. It is contained in human organisms in amount of about 21%. Everything surrounding us (living and nonliving organic worlds) also consists of carbon. Variety of modifications of carbon takes my fancy. There are a lot of modifications or allotropic forms of carbon where it exists in pure form, free of other elements. The most well-known of them are graphite (material for pencil leads), coal and diamond. One of the most amazing modifications of pure graphite is carbon nanotubes, shortly CNT. In this modification carbon atoms are linked in a long molecule which forms a cylindric tube. This tube can be single- or multi-wall. Multi-wall nanotube consists of several (up to dozens) nested tubes. As a result we have such a “Matryoshka” (nest doll).

So we study the structure of carbon nanotubes by means of electronic microscopy – transmission and scanning. We analyze their optical properties by means of light combination scattering, study their electrical and thermal properties.

Basing on these studies we synthesize carbon nanotubes with different polymers. Put simply, we mix carbon nanotubes with melted polymer and get composite material. Carbon nanotubes in polymer play role of filling material forming a sort of reinforcing rods. It provides new properties such as electrical conductivity, thermal conductivity, strength, firmness, which are absolutely noncharacteristic for polymers. These properties, in particular, possibility for producing of a material with these properties, are subjects for our studies. Currently we achieved 11-13 orders of magnitude increasing of electrical conductivity of polymer composite material!

- Ho you managed to achieve this result?

- The case is that electrical and thermal conductivity of carbon nanotubes is one of the highest. We saved this property in polymer composite due to conductive mesh formed by carbon nanotubes which provides conductivity of the material as a whole.

Increasing of electrical conductivity of epoxy resin (ER) by addition of vetically oriented CNT (composite ER/VANTs) and horizontally oriented CNT (composite ER/HANTs). From the article by N.G. Chechenin et al Appl. Surf. Sci. (2013) v. 275, p. 217-221

- How do you synthesize carbon nanotubes with polymers?

- Our group have developed several method for synthesis of carbon nanotubes and polymers, such as electric-arc deposition, glow-discharge deposition, gas-phase deposition with pyrolysis. Under the difference of the approaches these methods are similar in one: at first we have to destroy the compound which contains carbon, for instance, molecules of acetylene, and then to use carbon for the production of carbon nanotubes. We choose temperature, reactor's pressure, rate of the carbon-containing gas flux in order to form onle carbon nanotubes without admixture of other carbon modifications or allotropic forms. Then we mix produced in such a way carbon nanotubes with polymer.

- What are the advantages of these methods?

- By means of these methods we produce essentially big arrays of carbon nanotubes. Moreover they are produced in vertical direction, i.e. perpendicular to the base surface. These arrays are called “forests” of carbon nanotubes. We can produce them vertically due to continuous giving of catalyst during the whole process. As catalyst we use iron contained in ferrocene, which separate iron atoms during decomposition. Iron atoms are condensed on the base and stimulate growth of carbon nanotubes.

- How self-organization of carbon nanotubes is realized?

- Mechanism which determines production of carbon nanotubes is still unclear. At certain temperature and operation gases giving into the reactor the array of produced carbon nanotubes becomes sufficiently compact. Apparantly, high density is predefined by links of the nanotubes with pips formed on their surface. Besides, the pips keep nanotubes at the distance each from other, do not allow them neither to stick together, nor to curve while the growth of the tubes array is simulataneous and homogenious.

- Do you produce right-lined carbon nanotubes?

- Using tradiaitonal methods the produced nanotubes are rolled up in coils or in spiral dives. Using the method with continuous giving of catalyst during pyrolisys we get nanotubes with not absolutely right-lined,but more well-shaped forms. The tubes can form columns, but not sphere-like agglomerates, i.e. without sticking together. Our carbon nanotubeszre used as arrays. So no additional measures are required for carbon nanotubes agglomerates disassembly. The problems probaboly will arise in the case of single carbon nanotubes application. Than we'll solve a problem of their separation depending on characteristics we need. Today we do not solve this problem.

- What is the size of carbon nanotubes?

- In our Laboratory we get presumably multi-wall carbon nanotubes. Their outer diameter is from 15 nanometers, inner diameter 0 about 5 nanometers, the length is up to 2 mm.

- How safe are carbon nanotubes?

- The question about safety or hazard of carbon nanotubes is still unclear, therfore it is necessary to adhere to some measures. If carbon nanotubes are used in the form of powder, it is necessary to avoid its spraying. We need to work under air funnel and in rubber gloves, i.e. technological security measures usual for chemical laboratory. Mainly we work with carbon nanotubes fixed for instance, at silicon or some other base. They can be separated from the base as a sufficiently thick film (about 1 mm thick). So in this case we do not use spraying at all. Nevertheless we need to work in rubber gloves.

- Where carbon nanotubes can be used?

- Polymer composite materials with carbon nanotubes provide a number of unusual properties, so they can be used as protective coatings. Composites are also prospective materials for using as light shock-resistant materials, for instance, armor vests. The scientists study the possibility to use carbon nanotubes as filtering material due to their high chemical inactivity. Very interesting applications of carbon nanotubes in medicine, where they can be used as containers for medical reagents by bloodflow the the needed organ or affected region of the organ. Applications of carbon nanotubes, especially single-wall nanotubes, for nanoelectronics, PV and other similar fields are also very interesting, and currently part of them are under investigation.